If there was one man, other than my father, who could take credit for keeping our farm operating in the 50s and 60s when I was home, it would be John Graham. John ran the welding shop for the Landis (Sask) Coop from 1951 until he retired. Landis was a village located about 5 miles from our farm. Especially in spring and fall, farmers including my father, counted on him to keep their equipment running and he did. You could buy parts but no one could afford them.

The welding shop located behind the Coop Garage looked like an abandoned building. There was enough scrap metal in and around it to keep the furnaces at IPSCO (as it was then) going for a week. The inside was dimly lit as much of John's work was on equipment outside the shop. It was uninsulated but I figure John was impervious to heat or cold. The shop was a fascinating place for kids but you daren't go in there. There was always something hot or sharp or welding sparks or acetylene flame. You stayed out of the way.

John was about the size and shape of a square bale, maybe a bit longer. I know because I have seen him several times climb inside a bale chamber to chisel loose a broken bolt or similar. He was black with grease and soot from head to toe. He loved people and people loved him. His one good eye always had a twinkle and he loved to tease kids.

In 1966, spring was very late. I was home from university in April and dad told me to take the tractor and go and get a 16' rod weeder he had purchased at a local farm auction. The lane into the yard had been plowed out and the drifts were five feet high. I did not realize the lane narrowed in until it was about two feet narrower than the rod weeder. I was well and truly stuck in it and had bent the wings that stuck out to the side and drove the rod. Nothing to do but keep going. Dad laughed and told me to take it to John. The rest of the year John told everyone I had been working summerfallow and got caught between two snow banks.

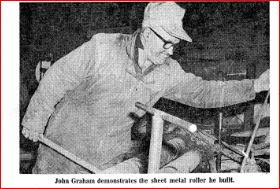

John was entirely self taught. He never finished highschool. His welding wasn't fancy but it held. He could rebuild shattered gears or make them from scratch on a lathe he built himself. He built his own forge, a sheet metal roller, a power hacksaw, a 50 ton press, a concave grinder, an adjustable power threader, a sheet metal bender, a three speed drill press that would take a 1" bit, and a power hammer. He never used blueprints for the tools he built. He invented a roller machine for putting the curve back in cultivator shanks that were bent when the shovel caught on a rock. Dad needed that machine several times for our 14' Graham Holme cultivator.

John was born in 1905 in Scotland on the estate of Earl Grey. His family emigrated to New Brunswick in 1909 where John at age 14 worked in a pulp mill. The family of five sons moved west in the 20's. His parents, Archie and Margaret, John and his older brother Tom farmed 2 miles east of our place. He lost an eye to a steel chip in the 1940s working at the Palo salt mine and said it took him four years to be able to judge distance again. Archie and Margaret passed away in the 60s and the brothers continued to batch in the home place. When Tom died in 1981, John stayed on.

John never married though he admitted he always liked the girls. When he was young he could "work all day and dance all night but now I just work all day". I do not know exactly when John retired. He was still working at age 81 though he took his time and took a few days off once in a while. He passed away in 1994 at age 89. No one took his place. Nor could anyone.

|

| Tom (L) and John (R). 1975. John had a clean cap that day |

|

| John in his work shop 1985 |

|

| John at home 1985 age almost 81 years |

Information for this post came from articles in the Coop Consumer 27/05/1975 and the Biggar Independent 31/12/1985. These were provided by John's niece Margaret.

He was the kinda guy who built the prairies alright. A lovely tribute!

ReplyDeleteThank you. I am sure there were many men like John in the prairie towns who kept the old equipment running for the small farmers. They are gone now and the new machine shops are hi tech and impersonal, like the big garages.

DeleteI wonder how many (if any) people like him still exist. This is a lovely tribute to a man who made a positive difference. Thank you.

ReplyDeleteThank you. Very few like John I expect. Modern machine shops are hi tech And the machinists will be trained and highly skilled. Repairing equipment worth hundreds of thousands of dollars is a different business.

DeleteI had an old school machinist in the bay next door. Francis was from Hungary and trained in the European tradition. He was always either creating or making a affordable version of an expensive automated machine. When trying to find help, when he would have to many projects, he would lament that he couldn’t find a machinist that could adequately run a conventional lathe or milling machine as well as weld and create! All they knew or at least wanted to do was work with CNC lathes and mills. He was not an old guy but trained in the traditional as well as modern CNC machinery. He was a true mechanical genius.

ReplyDeleteOur training or apprenticeship must be too short and too narrow compared to European.

DeleteI read this article with a smile on my face - thanks! In our rural community, the local inventor/blacksmith was Fred Smith. Like John Graham, he could make/invent/repair anything in his dark primitive shop. We still use the 'power hacksaw' he built from scrap metal - it saved hours of labour when we were cutting rebar for grain bins.

ReplyDeleteMy dad used to tell the following anecdote about the hacksaw: He and Fred had discussed the requirements and batted a few ideas back and forth, and it was left that Dad would give Fred a call later in the week to see how things were progressing. When he did, Fred said, "Well, I've figured out how it'll work. Now I'm figuring out all the ways it won't work."

I've often used that phrase when I'm working on some construction project. The initial idea is always the easy part!

What a great story. Too many people never explore the downsides. Your Fred Smith and John Graham were two of a kind.

DeleteEvery village or small community had a man like John. When I was growing up, ours was the local blacksmith John Westlake. I wonder if any of those genius practical men still exist in our modern world?

ReplyDeleteShammickite, I am sure there are. They just do not work in shops like John's anymore but rather well lighted, heated machine shops with modern tools as well as home-made. Many of the machines used in dry-land (rain-fed) farming were invented and developed in Saskatchewan by farmers working in their own machine shops in winter.

DeleteVery touching. Certainly, John and Tom were admirable people without whom their neighbors would have been hard-pressed to survive. Coming from a Gulf Coast state, I never saw a snow drift until I moved to Oregon, and pulpwood and truck crops were the agricultural activities. The nearest I've come to prairie farming was through reading Sinclair Lewis' book Main Street (which was set in Minnesota), and it was not a flattering view.

ReplyDeleteHi, Snowbrush. Yes, they were great people and great neighbours. Prairie farming is a challenge, this year again with record drought. Had my dreams come true, I would have been one myself.

Delete